WIRELESS CHAIN HOIST LOAD CELL

ELECTRIC CHAIN HOIST GO WIRELESS!

The need for live load monitoring and reporting is increasing in all industries, not only entertainment related, in order to provide a safer working environment.

The joint work between FLEXA and EXE TECHNOLOGY product development teams resulted in the integration of the Flexa Sensors platform on board the EXE RISE hoists. This wireless technology applied to electric chain hoist offers maximum freedom in handling hoists, covering distances up to 600 meters from the Gateway.

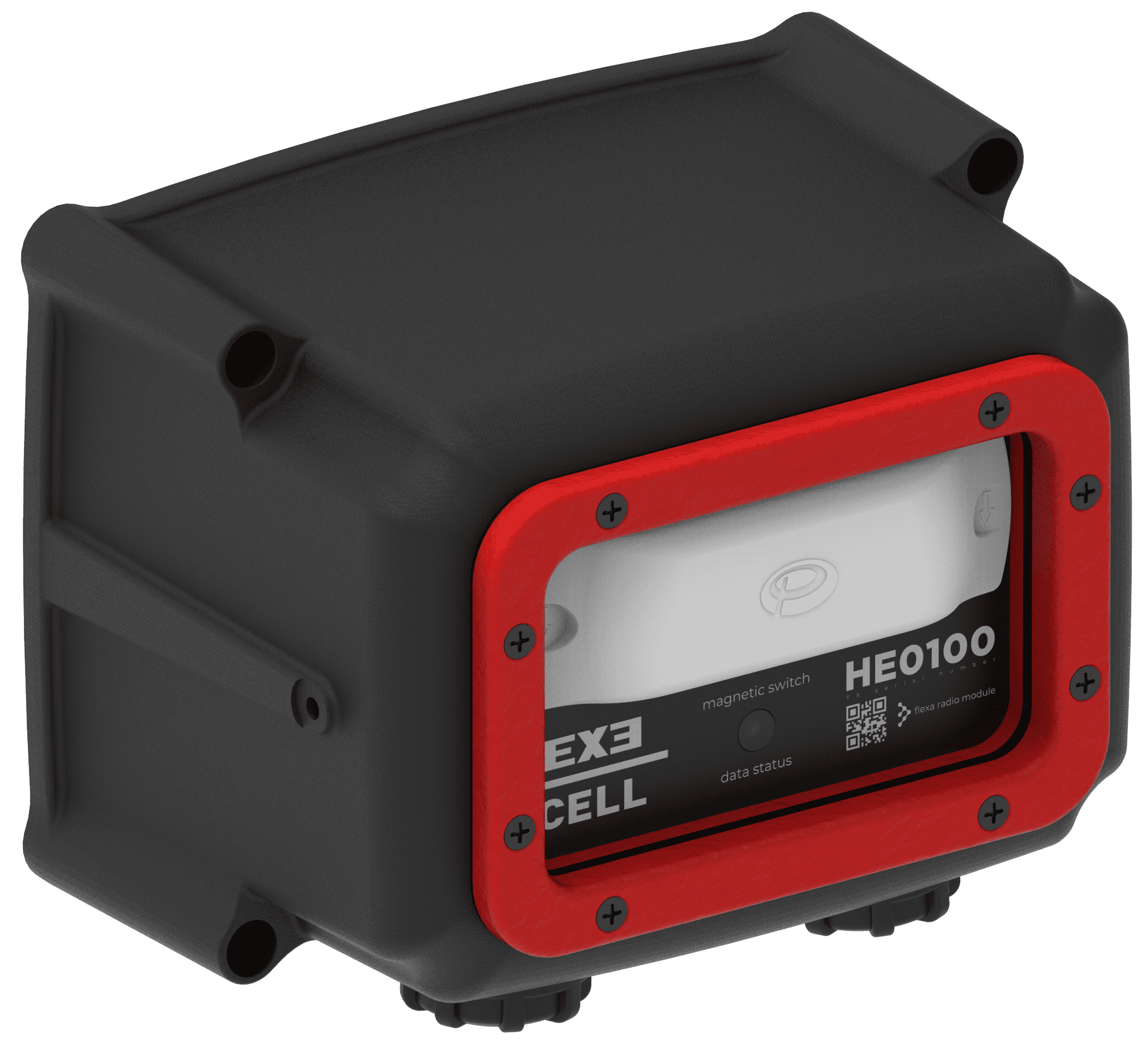

UNIQUE EXCLUSIVE DESIGN

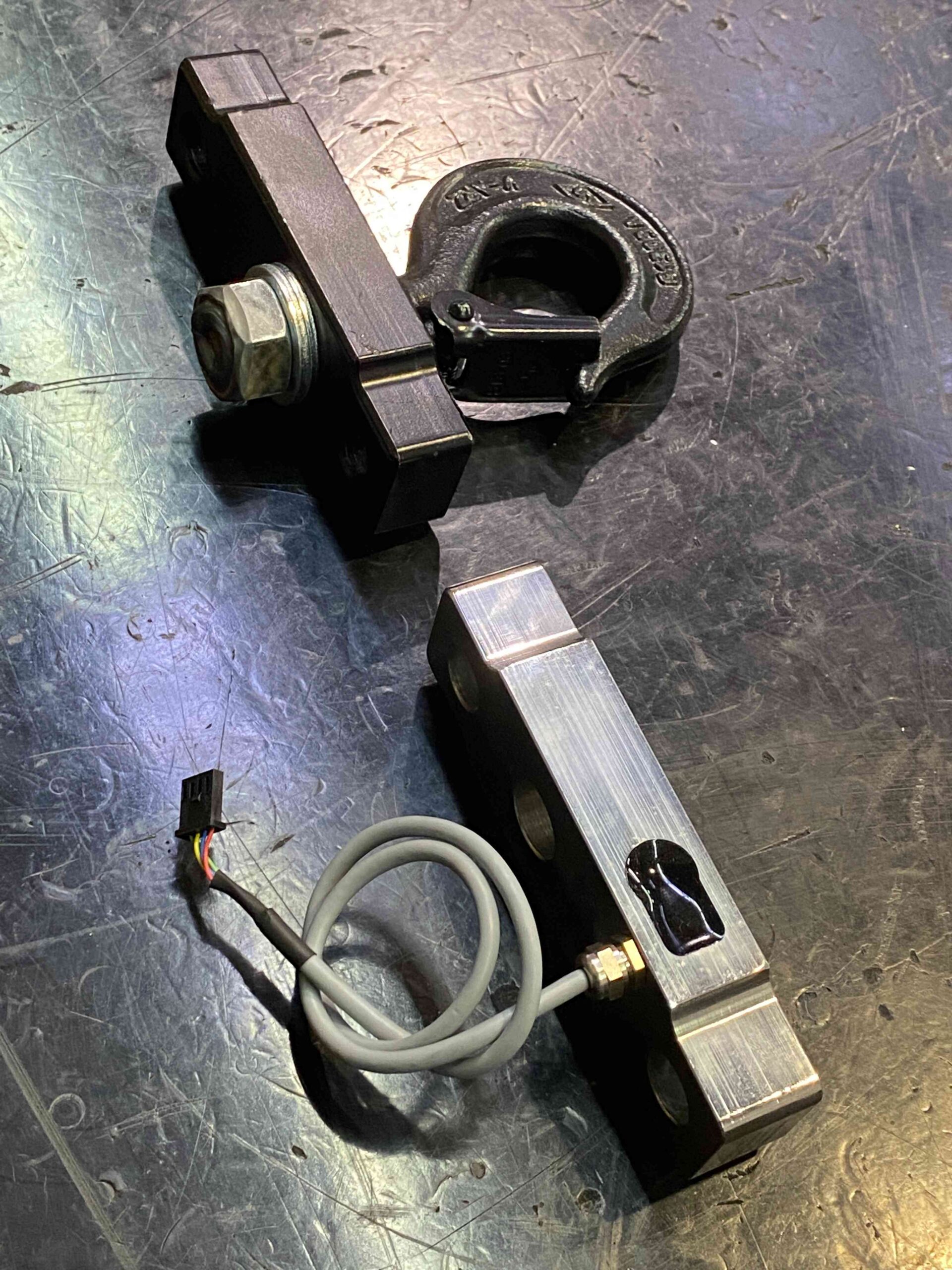

The Flexa module with the microprocessor and the radio section is mounted on one of the two hoist side covers. The externally mounted anti-shock antenna offers a high degree of efficiency even in difficult conditions for radio waves, such as in stage roofs. The module is connected to the EXE CELL system which integrates the load cell inside the motor hook of the EXE RISE chain hoists. The final result translates into a unique design and an unparalleled practicality of the product in the daily use.

HOW IT IS POSSIBLE

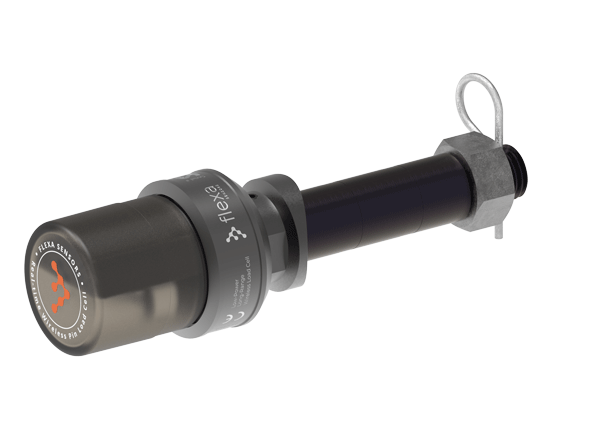

This emblematic image shows how the load cell can be integrated in the steel block that connects the electric hoist to its “body” support hook, thus eliminating external wires without losing any space in height compared to a solution based on an external cell… a true masterpiece of technology!

EXE WIRELESS LOAD CELL SPECIFICATIONS

From a standard EXE hook

Built to withstand the demands of touring

Fully integrated load-cell in chain-hoist hook

Between hoists and gateway 600 meters approx (additional repeaters can be added to further extend rangeB

Under the front panel for a high IP level. (the magnetic Reed is used to switch the cell module and radio transmission on and off and is independent of the hoist power supply)

Max No. of hoists (or cells) per system 100 units

Every 1 second

Every 1 second

According to the load status (when the load stabilizes, the rate decreases)

Automatically switches off in case of long inactivity to reduce battery consumption

Sub-1GHz

Can be easily set by the operator

Are powered with four C batteries to guarantee long lasting life (up to several years) with battery-saving smart transmission

With Flexa Wireless Load Cell System

Of Load Cell for easy setup without dismounting the hoist

Four C (R14) batteries to guarantee long lasting life (up to several years)

Are needed to access the batteries, all you need to do is un- screw the cap of the battery holders

Smart transmission strategy: it transmits every second when the load change exceeds a configurable threshold, transmits less often when the load is stable keep on reading every second

Multifunction RGB LED

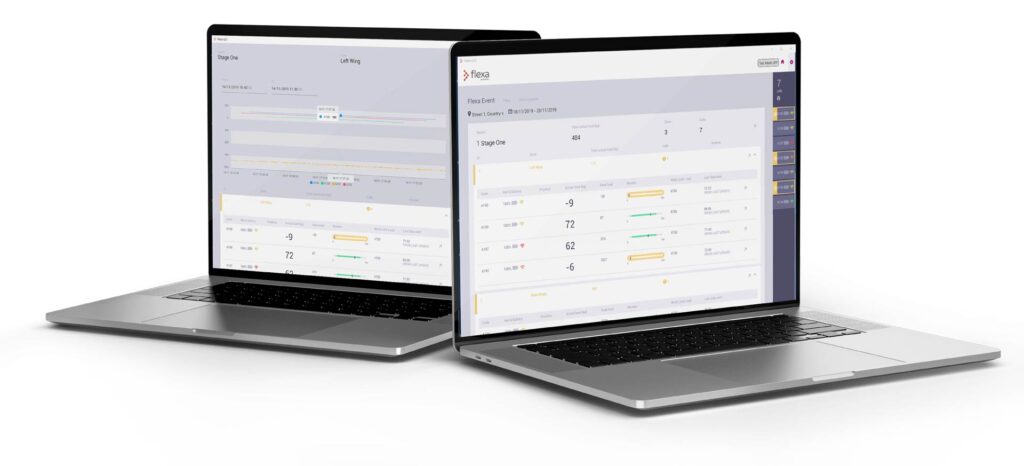

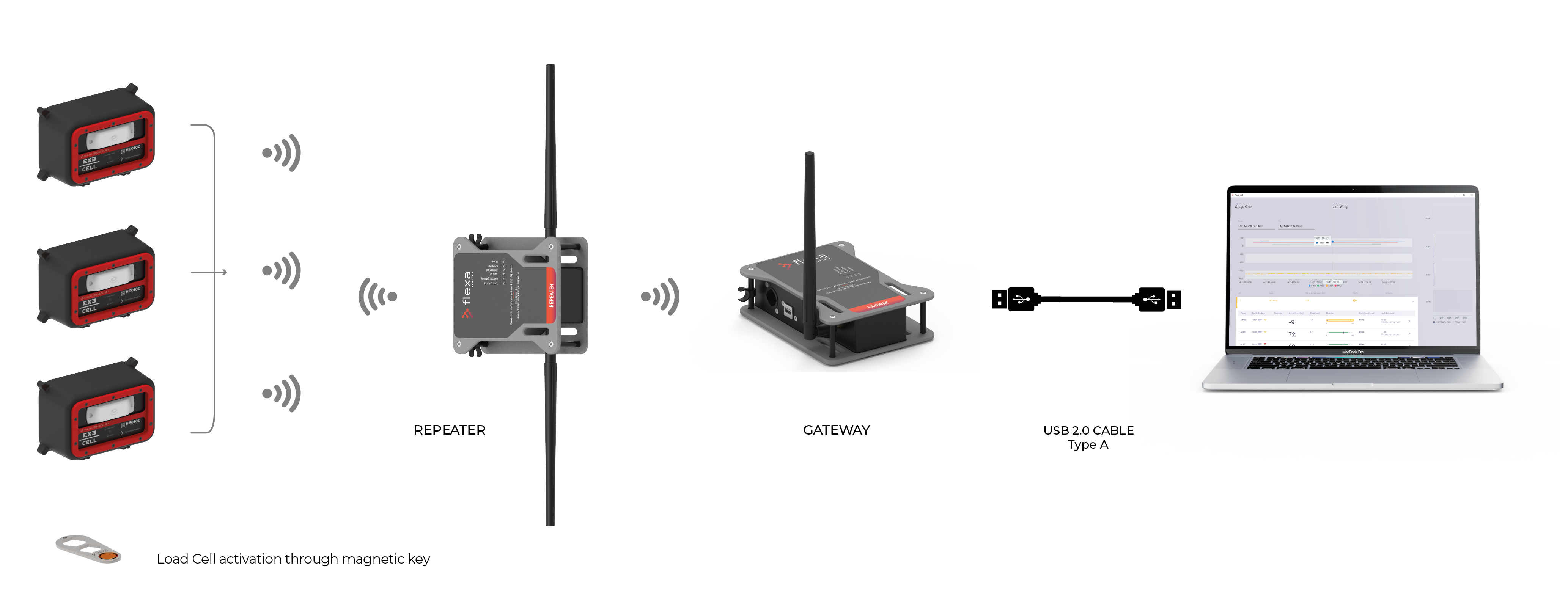

HOW IT WORKS

System designed to measure loads in real time with weight reading every second. Battery-saving smart transmission function, transmitting every second when the load change exceeds a configurable threshold, less often when the load is stable. The distances between the cells and the gateway depend on the environmental conditions (typically up to 700m in line-of-sight).

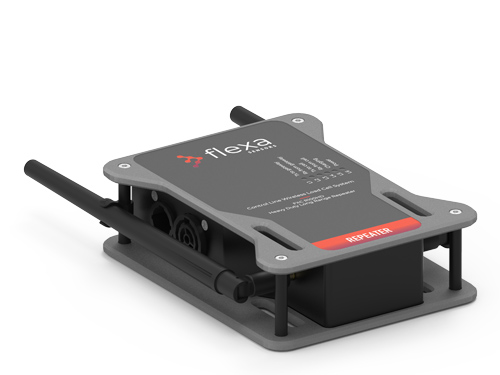

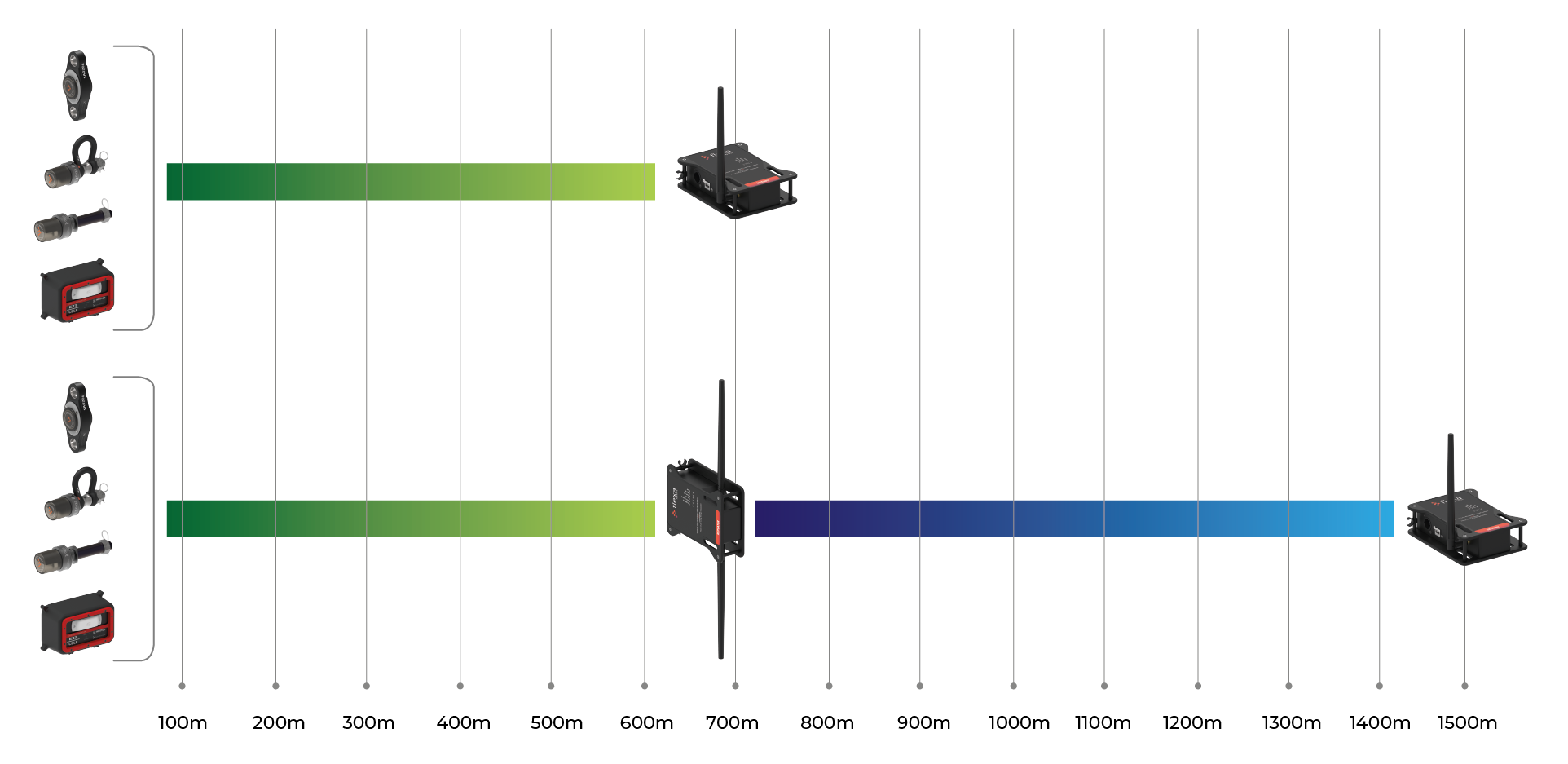

In case of problems in signal propagation, a repeater can be placed between the cell area and the gateway. The distances between the repeater(s) and the gateway depend on the environmental conditions (typically up to 700m in line-of-sight). Up to 5 repeaters can be managed by a single gateway.

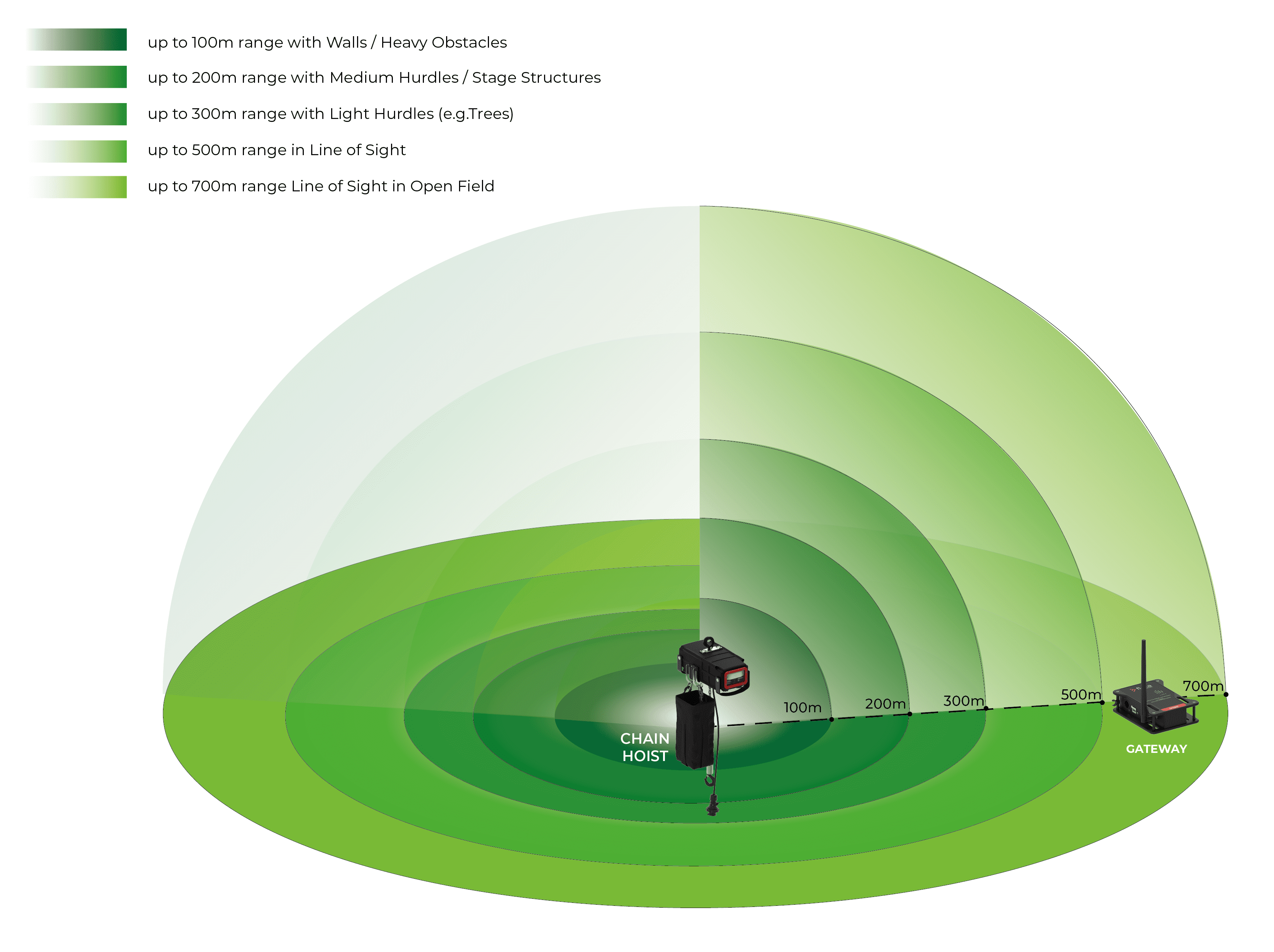

SIGNAL QUALITY AND TRANSMISSION RANGE

Every radio transmission is affected by environmental conditions. The distances calculated in line of sight on an open field are different from the real ones in presence of different obstacles. The graphs below show different ranges based on the environment in which the system operates.

Gallery

ASSEMBLED IN ITALY BY

Area Four Industries Italia S.r.l.

- www.areafourindustries.it

- info@areafourindustries.it

- VAT Number: IT 02748570245

- @flexasensors

- @flexasensors

- flexasensors

Enter your e-mail address in the box below to subscribe to the Flexa Sensors newsletter.

Your personal data will be processed according to the privacy policy.