WIRELESS TRUSS PIN LOAD CELL

SMART PIN FOR TRUSS AND TOWER

In case of complicated event set ups involving large and articulated structures it is useful or even necessary to know the dynamics of all loads involved.

The critical points are at the base of the towers and in the middle of the truss spans.

The Flexa Truss Pin has been developed and engineered to read precisely static & dynamic loads generated in these specific areas.

ONE MODEL AVAILABLE…

The immediately available model of Flexa Truss Pin works on HiPe Steel Truss System made by Conset.

…OTHERS WILL FOLLOW

The Truss Pin is a revolutionary concept but to make it available for the largest number of trusses on the market it has to be designed and tested model by model. We are currently engaged in the development of new versions and are open to any collaboration to provide this innovative product to those who need it for their truss fleet. Please contact our Customer Service for more information.

TAILOR-MADE FOR EACH OF YOUR TRUSS MODEL

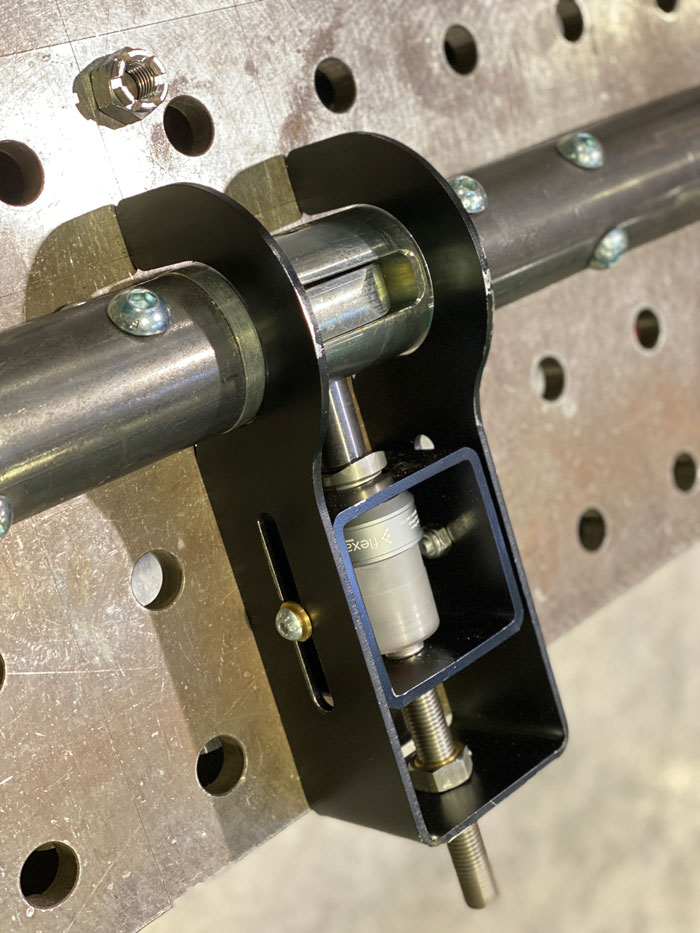

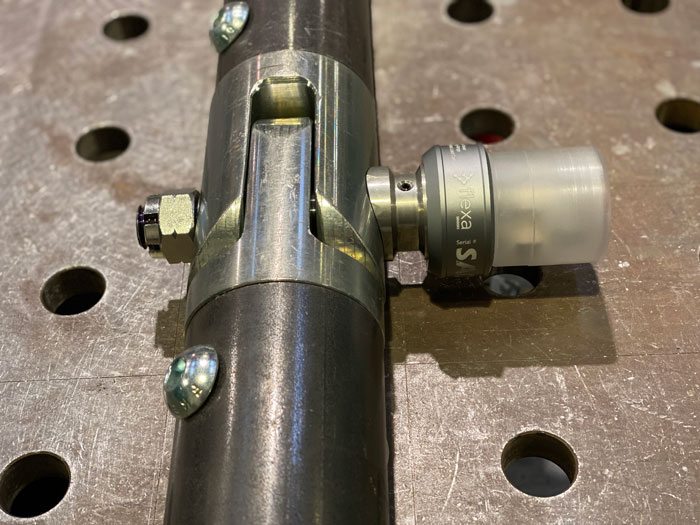

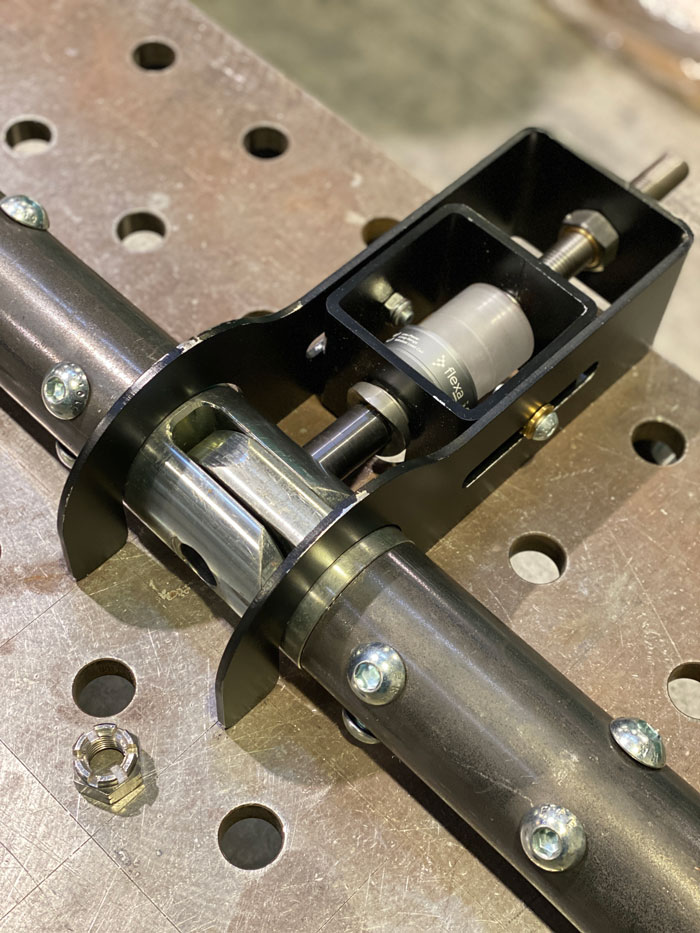

The Truss Pin works specifically by replacing the original truss manufacturer’s pin within a truss fork connection system. Consequently, each Truss Pin will have specific lengths and diameters: it’s built to seamlessly replace the original pins, but with the ability to read the forces involved.

For technical reasons, the Truss Pin cannot have diameters less than 24mm. Each model of Truss Pin must be authorized by the truss manufacturer and must appear in the corresponding data sheet.

GENTLY CONNECT

The Truss Pin replaces the original pin but, of course, you cannot use the hammer to insert it between the forks. We have developed a special tool that pushes (or pulls) it in a controlled manner to safeguard the electronics.

WIRELESS TRUSS PIN LOAD CELL SPECIFICATIONS

Built in acordance to the techical specifications of the truss manufatureres

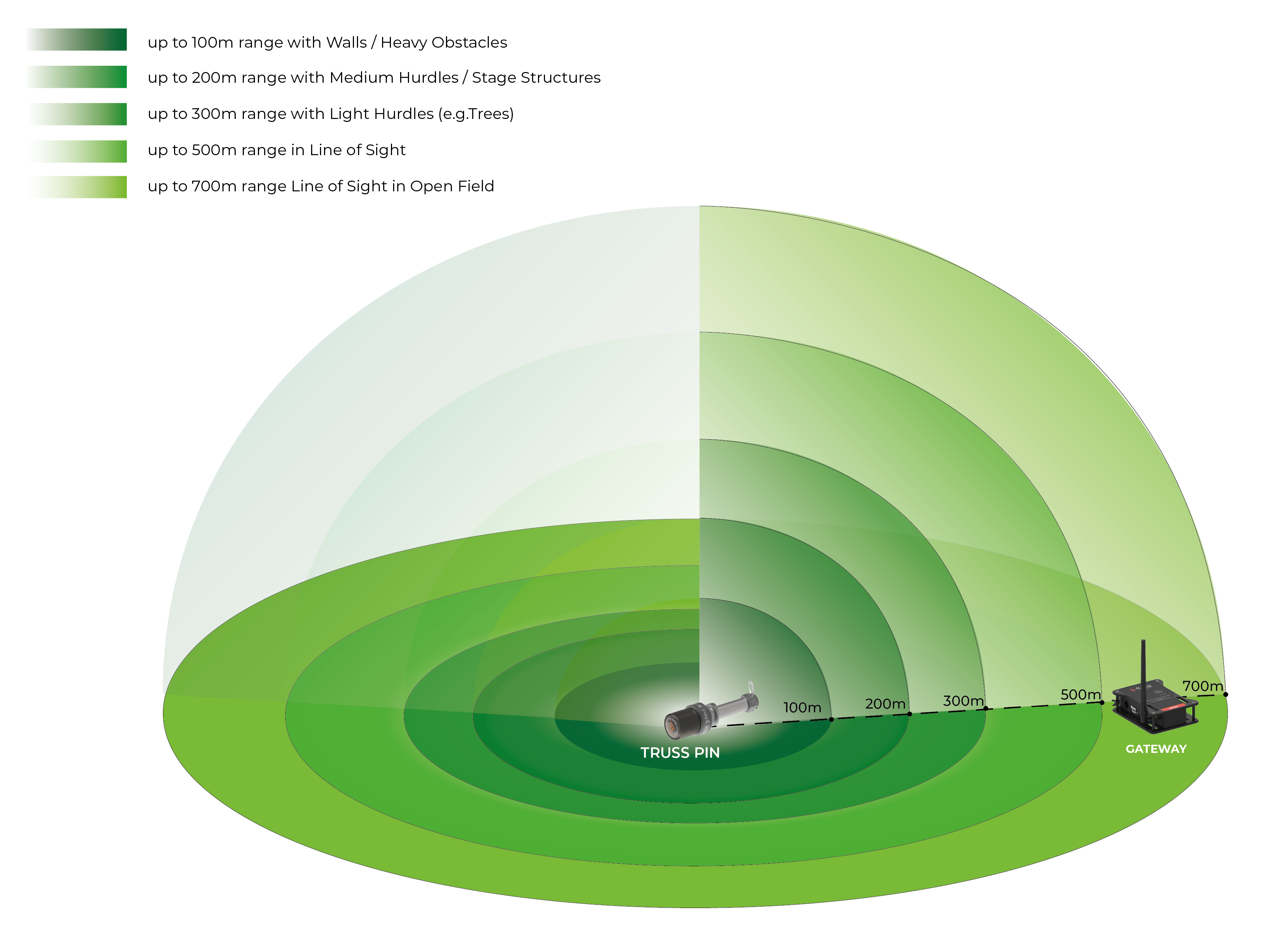

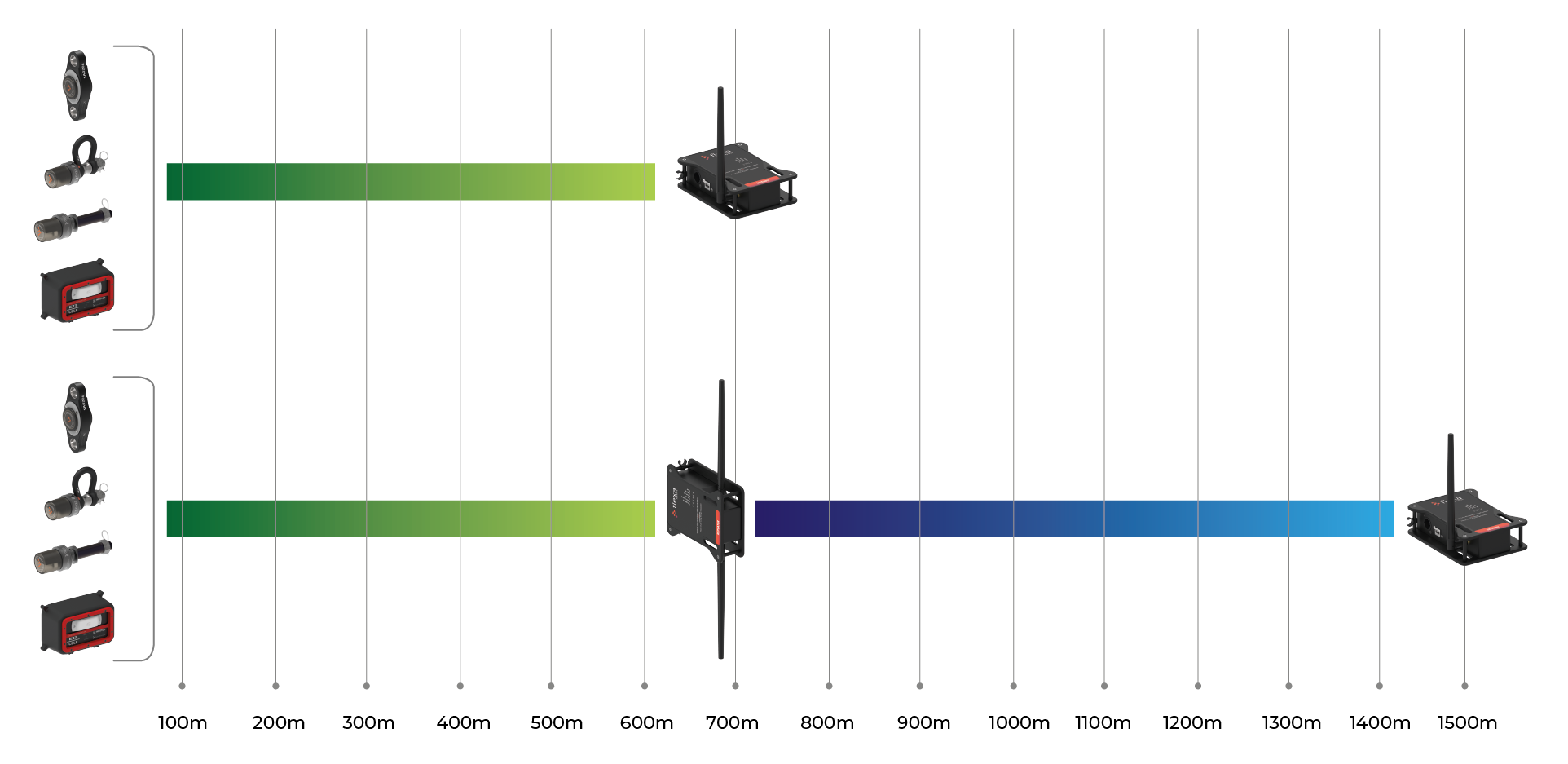

The theoretical range is always calculated as 600m in line of sight in an open field. However, when the pins are mounted on the tower bases there may be limitations due to the presence of metal structures all around.

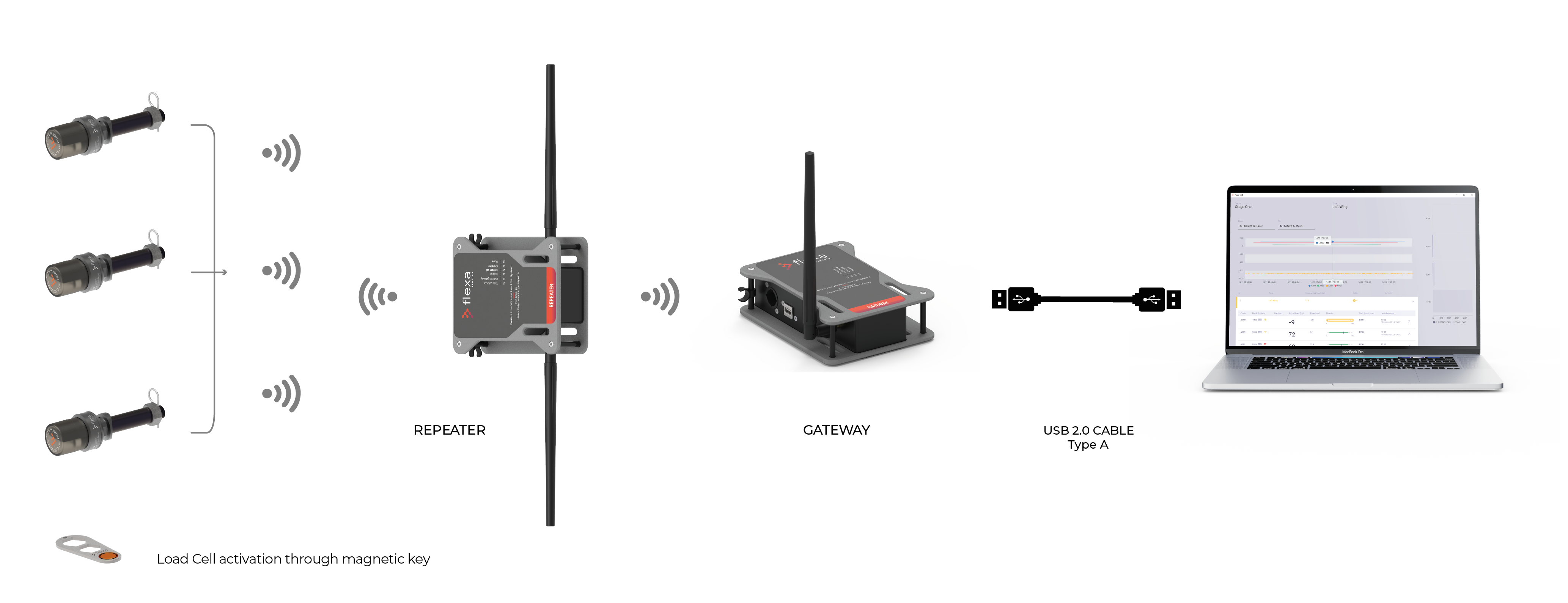

The Truss Pin uses the same electronic section as the Wireless Shackle Load Cells series and can be integrated with all devices on the Flexa Wireless Control Line platform.

100 units (including Wireless Load Cells and Wireless Chain Hoist Load Cells)

Sub-1GHz

With Magnetic Key (or any other magnet)

Multifunction RGB LED

IP67

2 x CR 123 (battery replacement without tools)

According to the load status (when the load stabilizes, the rate decreases)

Every 1 second

Every 1 second

HOW IT WORKS

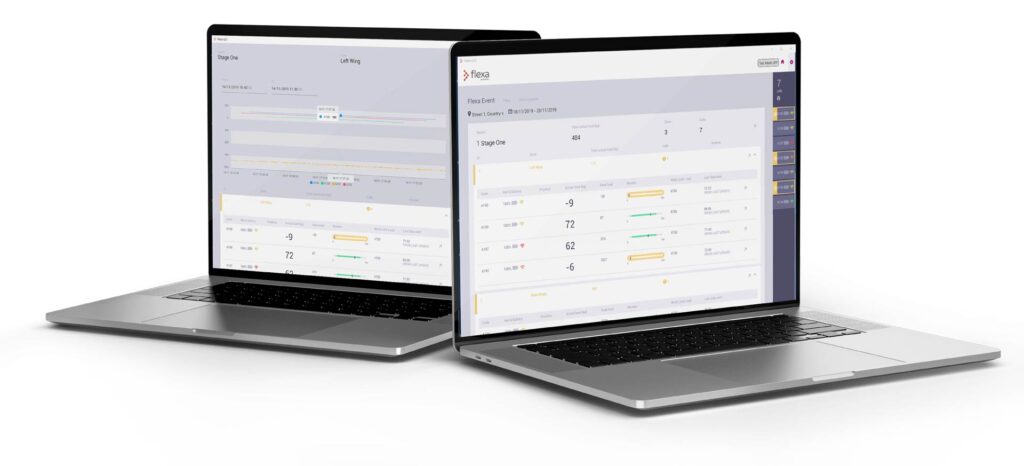

The load is read for each of the fork connections. The load data is available on the Flexa Control software interface and can be aggregated and named for each tower or beam. The data is refreshed every second. Battery-saving smart transmission strategy transmitting every second when the load change exceeds a configurable threshold, less often when the load is stable. The distances between the Truss Pins and the Gateway depend on the environmental conditions (typically up to 600m in line-of-sight).

In case of problems in signal propagation, a repeater can be placed between the cell area and the gateway. The distances between the repeater(s) and the gateway depend on the environmental conditions (typically up to 700m in line-of-sight). Up to 5 repeaters can be managed by a single gateway.

SIGNAL QUALITY AND TRANSMISSION RANGE

Every radio transmission is affected by environmental conditions. The distances calculated in line of sight on an open field are different from the real ones in presence of different obstacles. The graphs below show different ranges based on the environment in which the system operates.

TUTORIAL VIDEOS

OPERATIONS OVERVIEW

ASSEMBLY TRUSS PIN

How to fit the Truss Pin into the truss

FASTEN TRUSS PIN

How to fasten the Truss Pin to the truss

DISASSEMBLY TRUSS PIN

How to remove the Truss Pin from the truss

Gallery

ASSEMBLED IN ITALY BY

Area Four Industries Italia S.r.l.

- www.areafourindustries.it

- info@areafourindustries.it

- VAT Number: IT 02748570245

- @flexasensors

- @flexasensors

- flexasensors

Enter your e-mail address in the box below to subscribe to the Flexa Sensors newsletter.

Your personal data will be processed according to the privacy policy.